Duplex Boards Explained: Types, Uses, and Why Quality Matters

Duplex boards play a crucial role in modern packaging, thanks to their strength, versatility, and cost-effectiveness. At Tulsi Paper Mill Pvt. Ltd., we specialize in manufacturing high-quality Grey Back and White Back Duplex Boards, ensuring that every sheet meets the diverse needs of industries worldwide.

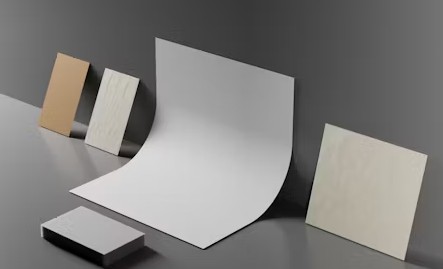

But what exactly are duplex boards? In simple terms, these are paperboards made by bonding two layers of paper pulp together, often with a coated surface on one side. The coating not only improves printability and appearance but also enhances durability and resistance to moisture and wear.

There are two primary types we produce: Grey Back Duplex Boards and White Back Duplex Boards. Grey Back boards feature a grey recycled surface on one side, making them a preferred choice for packaging where the inside isn’t visible. White Back boards, with a cleaner white reverse side, are ideal for premium packaging, boxes, and display cartons where aesthetics matter just as much as strength.

The uses of duplex boards span across industries: food packaging, garment boxes, pharmaceuticals, toy packaging, book covers, and much more. Their excellent stiffness and foldability ensure that products stay protected, while the smooth surface makes them perfect for high-quality printing and branding.

At Tulsi Paper Mill, we believe quality is more than a specification — it’s a promise. From sourcing recycled raw materials to adopting modern manufacturing practices, we ensure every batch meets international standards for strength, finish, and consistency. This commitment helps businesses reduce product damage, enhance brand perception, and build customer trust.

Whether you’re a brand owner, printer, or packaging supplier, choosing the right duplex board can make a difference in performance and sustainability. Explore our range and discover why quality matters when it comes to duplex boards.